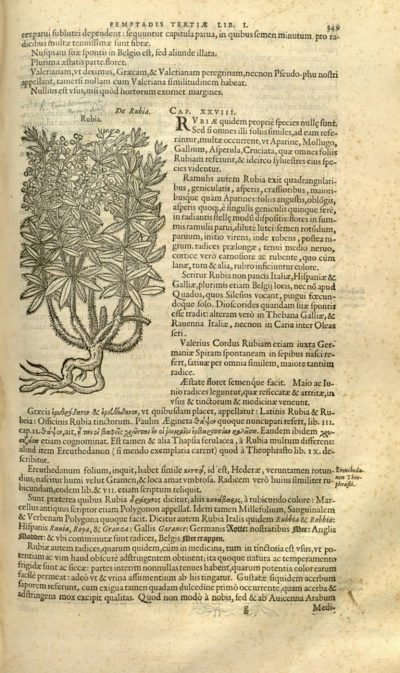

In his Stirpium historiae pemptades sex (1583; abbreviated here as the Stirpium), the Mechelen physician and botanist Rembert Dodoens (1517–1585) remarked that the root of the madder plant is used as a red dye (‘tum in tinctoria est usus‘).[1] An important figure in the history of early modern botanical knowledge, Dodoens, along with two other Netherlandish botanists Carolus Clusius (1526–1609) and Matthias Lobelius (1538–1616), and their main publishers Christophe Plantin (c. 1520–1589) and the successors of the Officina Plantiniana (Plantin Press), collectively ushered in the new discipline of botany to the sixteenth-century Low Countries with their many printed botanical treatises.[2] An interest in plants was already growing strong in the Antwerp region since the late Burgundian period.[3] The first printed herbal in the southern Low Countries, Den herbarius in dyetsche (1484), was published by Johan Veldener in Leuven. The book was later printed in the city periphery in 1511 by Govaert Back, and a demand for similar works developed steadily.[4] Between the 1530s and 1560s, eighteen botanical publications of the 382 editions now deemed scientifically significant on the European level were produced in Antwerp; these publications included Dodoens’s first comprehensive herbal, the Cruijdeboeck, published in 1554 by Antwerp publisher Jan van der Loe.[5] Dodoens’s Stirpium is a renewed edition of the Cruijdeboeck with largely expanded text and new woodcuts. The Stirpium marks a new height of botanical knowledge in the Low Countries and was highly popular and largely circulated throughout Europe.[6] As the European herbal tradition is deeply rooted in medicine, the entries in the Stirpium mostly describe the medicinal properties of the plants.[7] However, widespread utilitarian functions sometimes find their ways into the writings of the physician-botanist, albeit most often brief and in passing. The artisanal use of the madder root as a red dye is such an example.

(Above) Reworking black woodblocks and a replica press with Jessie Wei-Hsuan Chen, Plantin-Moretus Museum Antwerp. A film by Katrien Vanagt and Stefano Bertacchini, 2020 @Serafín Productions for ARTECHNE

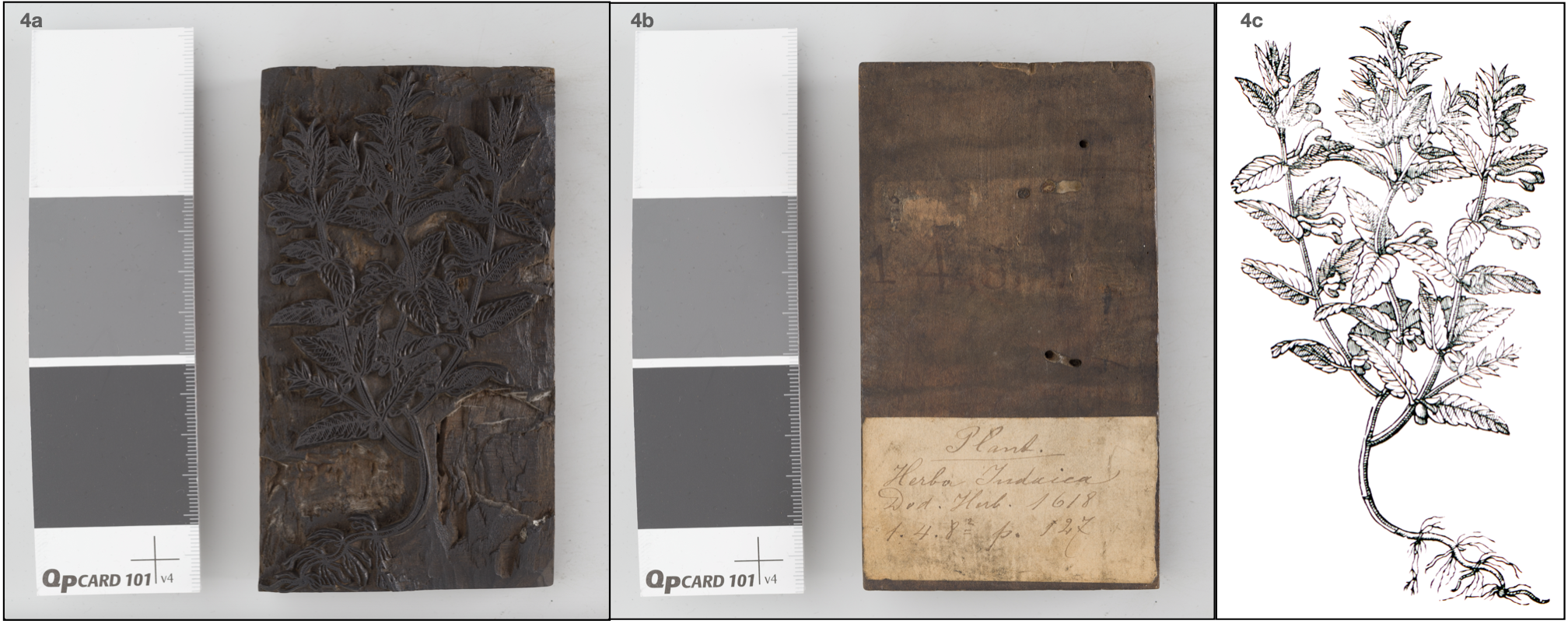

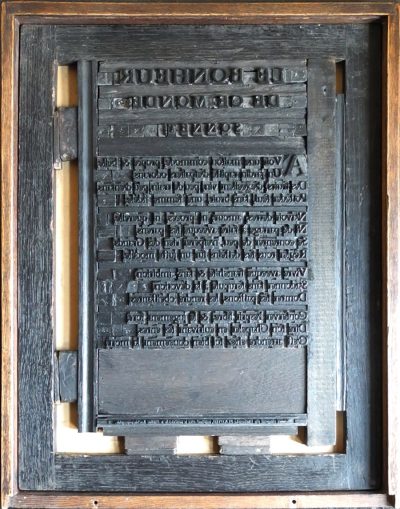

Dodoens’s description is accompanied by a woodcut of the madder plant [Figure 1]. The original woodblock [MPM.HP.05944; Figure 2a-b] that printed this illustration more than 400 years ago is still extant. Together with just more than 4,000 woodblocks that carry images of plants and were used to print the woodcuts in the books of Dodoens, Clusius, Lobelius, and other contemporaneous botanists, the woodblock of the madder is now preserved at the Museum Plantin-Moretus (MPM) in Antwerp.[8] The madder block measures around 7.1cm in width, 13.1cm in length, and 2.2cm in thickness. It is light in weight and can be easily held in one hand. One of the most striking features of the woodblock is its noticeable dark colour, an almost black surface that is slightly glossy under light. The dark colour is caused by early modern printing ink, which was a mixture of lamp black with an oil-based varnish that was usually obtained by burning oil. Ink making was highly demanding and potentially dangerous because it required equipment and dedicated space, as well as long and regular attention to prevent explosions caused by over-burning.[9] Good quality ink yielded from this painstaking process gives a rich lustrous black to the printed images. The ink applied onto the woodblock could not be fully cleaned off after each print job, and eventually the dark colour covers the natural brown hue of the wood. However, such a simple explanation of why the madder block is black elides the complex story of how it got to this state. The dark complexion of this humble small block contains the long printing history of the madder image that visualised the plant to early modern herbal readers. The woodblock is a witness of the skills and embodied knowledge of the individuals that practised another type of black technology, that of printing black and white book illustrations. The printing technology sprouted in the Low Countries during the late Burgundian period around 1470s, and Antwerp bloomed as the printing capital by the time Plantin became a prominent printer–publisher.[10] For the madder block, the process of becoming black is a series of material transformations performed by the individuals at each stage of the block’s existence. This book chapter demonstrates these stages of a woodblock’s transformations, and it further identifies the skills and the embodied knowledge that are critical in producing high-quality printed images in early modern Europe through the madder block.

From a Piece of Planed Woodblock to a Printing Matrix

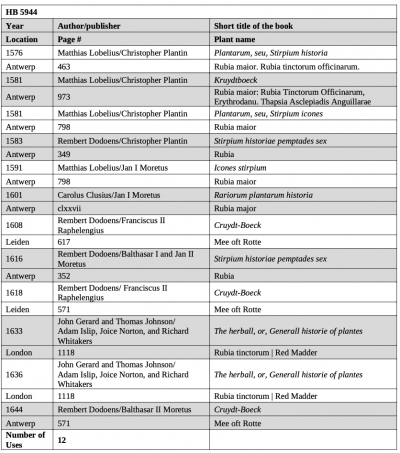

The madder block was regularly selected to illustrate the plant at the Officina Plantiniana between 1576 and 1644. During this period of almost seventy years, this block printed the madder woodcuts in twelve publications by several botanists [Table 1]. On its own, a single woodblock is not expensive to commission. However, as early modern herbals usually included from several hundred to more than 2,000 woodcuts, the accumulated cost could be exorbitant. As a result, a stock of woodblocks would be important capital for a printer-publisher, and reusing and recycling them for different publications was a common practice.[11] The madder image appeared for the first time in Lobelius’s Plantarum, seu, Stirpium historia in 1576, and the block may have been commissioned by Plantin for this herbal. According to records in the business archive of the Plantin Press, woodcutter Antonie van Leest (active 1566–1584) was paid at 13 st. apiece to cut 708 botanical blocks for this project. Woodcutter Gerard Janssen van Kampen (active 1564–1583) cut another 74 blocks, and he received 15 st. for each.[12] With almost 800 woodblocks of plant depictions created for Lobelius’s herbal, and more than 600 already in the stock of the Plantin Press for the publications of Dodoens and Clusius, Lobelius’s herbal was thus able to illustrate more than 1,400 plants, including the madder. The payments for the cutters, however, document the stage when a block of wood transformed into a printing matrix, which is already a later stage in the full process of making a woodblock.

A printing matrix is a support of any material that carries an image in order to be printed, and it was an essential device for the early modern technology of black image printing.[13] The woodblock is a relief printing matrix for woodcut, and copperplate is used as an intaglio printing matrix for engraving and etching. There are two major differences between relief and intaglio printings: the ways in which the printing matrices are inked and the presses used to get an impression of the image. A woodblock prints what remains after cutting, which means that when printing relief, the ink is applied to the raised lines on a block, which is the same way printing types are inked. Thus, text and image can be printed at the same time when illustrating a book with woodcut. A copperplate, on the other hand, prints what is removed. The ink is rubbed into the grooves and the uncut area is wiped clean before printing. To pick up the ink of an intaglio plate, a high-pressure rolling press is required.[14] Because a different type of press is needed to print copperplates, a page needed to go under the press two times — one to print the text and another to print the illustration — if a book printer wanted to incorporate engravings or etchings into a book. This would add to the production time and cost. Even Plantin, one of the biggest printer-publishers of his time, did not print his own engravings and etchings, despite there being a rolling press, entered in the inventory of the Officina Plantiniana in the last quarter of the sixteenth century. Plantin and his successors continued to outsource the printing of intaglio plates to local printmakers in their network.[15] Relief printing, on the other hand, did not pose the same problem, and hence printing woodblocks was done in-house.[16] This allowed the herbals of Dodoens, Clusius, and Lobelius to include hundreds to thousands of images.

Composing

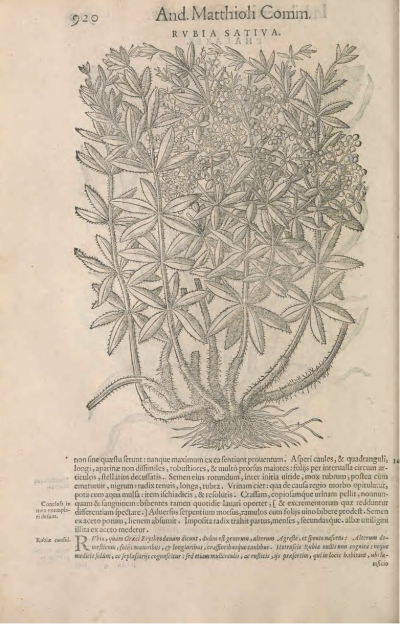

To go from a piece of planed woodblock to a printing matrix, the madder block underwent two major stages of transformation: the composing phase and the cutting phase. Critical in this process was plausibly the draftsman Peeter vander Borcht (1535/40–1608). The birthplace of Vander Borcht is unknown, but it is generally agreed that he was born in Mechelen — the same hometown as Dodoens.[17] In 1565, Dodoens sent Plantin some sketches of plants by Vander Borcht. This event jump-started the illustration career of the draftsman, who remained under Plantin’s commission for an extended period throughout the sixteenth century.[18] Vander Borcht is credited as the draftsman for most of the botanical illustrations produced by the Plantin Press.[19] It is important to note, however, that drafting a depiction of a plant does not necessarily mean drawing the specimen from life. Copying images was a common practice, and sixteenth- and seventeenth- century botanical treatises mostly reproduce images from existing visual sources.[20] For example, the image printed by the madder block [Figure 1] and the woodcut from the herbal of the Italian naturalist Pietro Andrea Mattioli (1501–1577) from 1565 [Figure 3] share conspicuous similarities.[21] The roots of the madder are much more prominent in the Flemish version, emphasising the plant part that produces the red dye. However, the placement of the leaves and fruit, as well as the inclusion of the broken furry stems, resemble the artistic decisions made for Mattioli’s woodcut. While it is not a direct copy, it is a highly possible source image the draftsman would have seen before composing the image for the madder block.

There is a long-standing question of whether Vander Borcht made his illustrations directly on the woodblocks or if preparatory drawings — presumably done with quill and ink on paper — were sketched before they were transferred onto the blocks.[22] Even though Vander Borcht could have been very skillful, the task of drawing hundreds of different plants with various kinds of shapes and details freehand without any preliminary planning would have been challenging. In addition, as mentioned, Dodoens sent Plantin some drawings of plants by Vander Borcht, indicating that there was a sketching stage before the images were drawn onto the woodblocks. The survival rate of preparatory drawings is very low, partially due to the possibility of them being destroyed during the process of transferring an image onto a woodblocks.[23] Nevertheless, a few drawings for the new woodcuts added in Dodoens’s 1608 Cruydt-Boeck, the first Dutch translation of Dodoens’s Stirpium, were brought to light at the now closed Amsterdam Zoological Museum in 1943.[24] They include a drawing for the image of block MPM.HB.06241 [Figure 4a-c] at the Museum Plantin-Moretus. Although these drawings were never indubitably attributed to Vander Borcht, they reinforce the idea that some sort of preparatory work for the botanical illustrations would most likely have taken place before a finalised image was transferred and fully rendered onto a woodblock.

Cutting

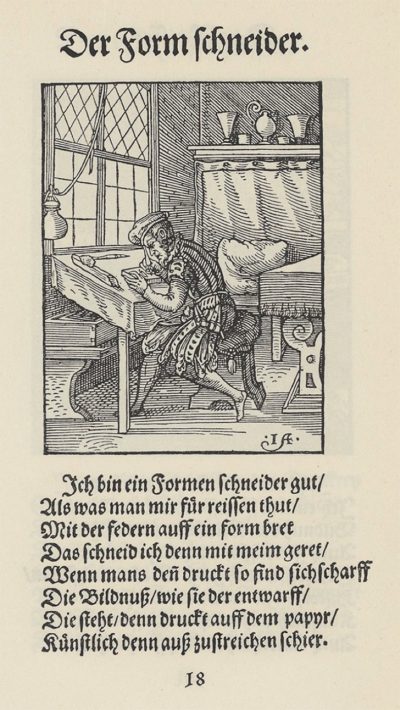

After the block’s first transformation — from a planed block to a drawn block with the transferred depiction of the madder — it was handed to the woodcutter, either to Van Leest or Van Kampen. As stated, a relief prints what has not been cut away from the woodblock, thus, the cutters needed to work in reverse and remove the areas that would become the white space in the printed impression. To undertake this work, they used a simple but effective cutter’s tool. A woodcut by Jost Amman from a famous book of trades [Figure 5], Das Ständebuch (1568), depicts a cutter working with a small knife, and there is another one in front of him on the table.[25] The knife is usually a piece of steel with a pointed tip, with the bevel of the blade set on one side; it has a wooden handle to help the woodcutter better grip the tool.[26] Although the burin was already used by engravers during the sixteenth century, a woodcutter would not have used the tool in this period. Working with a knife, the process of cutting the madder block consisted primarily of making ‘strokes’ in order to achieve various types of linework. For every line, a cutter needed to make two strokes on both sides of the line, whereas an engraver would only need to carve a groove in one stroke with a burin, which becomes a line in the printed image. In particular, cross-hatching was difficult and time-consuming to execute for a woodcutter. To cross four lines in each direction, an engraver needs to make eight strokes with a burin, but a woodcutter needs to make seventy-two strokes to remove all the diamond-shaped spaces in between.[27] As a result, to cut the shaded leaf towards the bottom of the madder [Figure 6], not including the furry texture on the outside of the leaf, the cutter would have needed to make a minimum of ninety tiny strokes in an area smaller than 1cm in width. This is probably why, contrary to what has been normally believed, skillful woodcutters were sometimes paid more than engravers for the same design. Woodblocks were also attractive investments because a woodblock was more durable and could ensure many more printings than a copperplate.[28] This meticulous cutting process transformed the madder block into a functional printing matrix.

Printing the Matrix: Skills and Embodied Knowledge

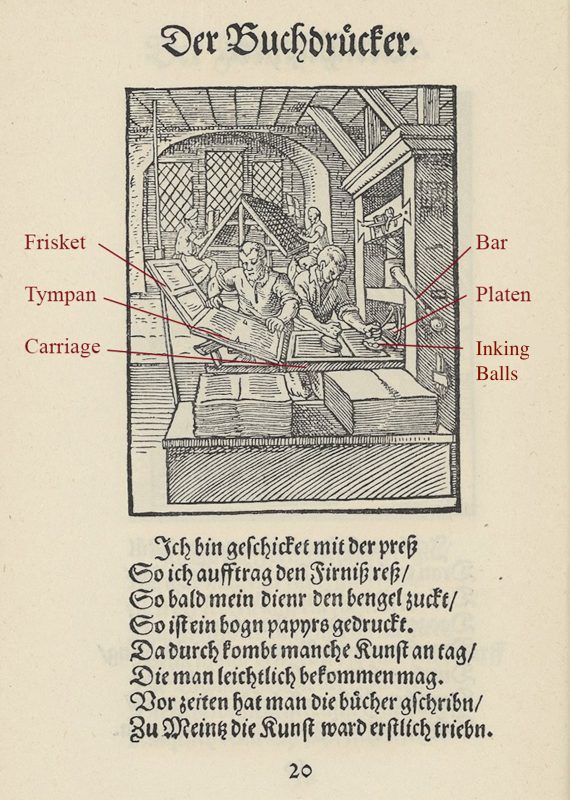

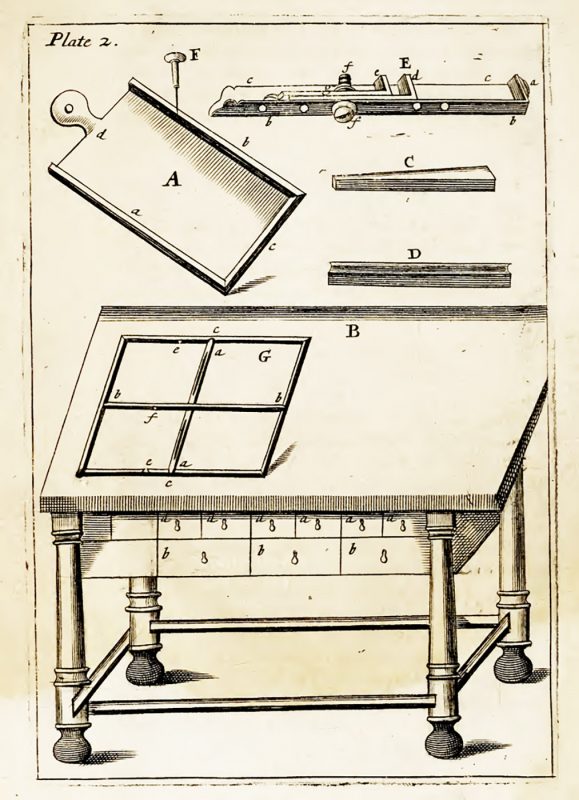

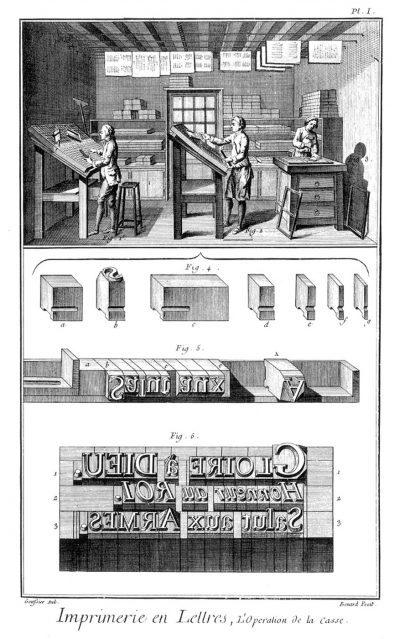

The printing stage is where the printing matrix of the madder image gradually transformed into a black woodblock over the seventy years of illustrating books for the Officina Plantiniana. To better grasp the process, it is perhaps useful to first provide a simplified and streamlined picture of the steps of printing before delving further into the details of these tasks. At the print shop of the Plantin Press, a compositor would follow Dodoens’s or Lobelius’s manuscripts (or would follow printed pages for reissues) letter-by-letter to pick up individual pieces of lead type that would constitute the sentences. He would compose one page at a time and insert the corresponding woodblock for illustration into the so-called forme (the layout of a page in its material format; Figure 7) during this stage.[29] Once the types and blocks were set, the forme would then be transported to the press and secured onto the carriage or bed (the platform to hold the forme; Figure 8) for a test print. After a proofreader corrected the printed proof, the print job could officially start. Two pressmen would operate the press. One pressmen (inker) would ink the forme by applying a thin layer of printing ink to the laid-out pages before the other pressman (printer) completed the rest of the motions to print a sheet. To distinguish between the different tasks of a pressmen, the terms ‘inker’ and ‘printer’ will be referred to when discussing the specific skill sets related to their tasks. Inker and printer do not, however, represent actual positions in a print shop. A pressman would most likely need to possess both skills to perform his work. While the inker was applying ink, the printer would place a sheet of paper onto the tympan (paper holder) [Figure 8], which would have been wet the day before to guarantee that the printers would have the materials readily available at the beginning of the workday. The printer would then close the frisket (flap), roll the carriage under the platen, and pull the bar to press before he would then roll the carriage back to its original position, open the frisket, remove the printed sheet from the tympan, and place it on a drying rack. This procedure would be repeated over and over until it reached the number of the print run for the book. Afterwards, the blocks and types would be taken apart by a typesetter to be cleaned and stored. The printed sheets would be wet again so that their verso side could be printed. Once both sides were done, and the quires dried and were handled by a collator for assembly, a copy of an herbal would be ready to go to a bookseller.

This printing stage is mechanical and repetitive, and the individuals who performed the work for the aforementioned processes are usually poorly documented, despite being an integral part of printing black-and-white book illustrations, and by extension printing books in the early modern period. This section thus identifies the crucial skills and embodied knowledge in working with this technology to recognise the contribution of these individuals. Among the many people in the print shop, three would physically work with the blocks: the compositor and the two pressmen (inker and printer). Because of this hyper-specialised structure for the division of labour in a print shop, the skills and the physical movements of the print staff are more integrated than with other roles. Most of the skills and tools required by a good print staff were crucial as they worked with the tools to set the type, ink the forme, or pull the bar. Indeed, the tools of the print staff were perhaps the most complex and elaborate ones in the process, especially when compared to those of a draftsman and cutter. While mastering drawing and cutting require the keen and careful manipulation of the instruments, the tools themselves are quite simple. To start making marks with a quill pen and ink, or even with a woodcutting knife, is rather straightforward; to start setting types or operating presses, however, requires at least some basic understanding of the printing technology. Two technical inventions were especially crucial around this technology, not only for printing the madder block, but for the whole of early modern European book printing industry: the making of printing types and the development of the hand press.[30] Type casting enabled the compositor to set the types and insert the madder block into a printing forme, and the hand press enabled the pressmen to print the sheets for the book.

Setting Types and Images

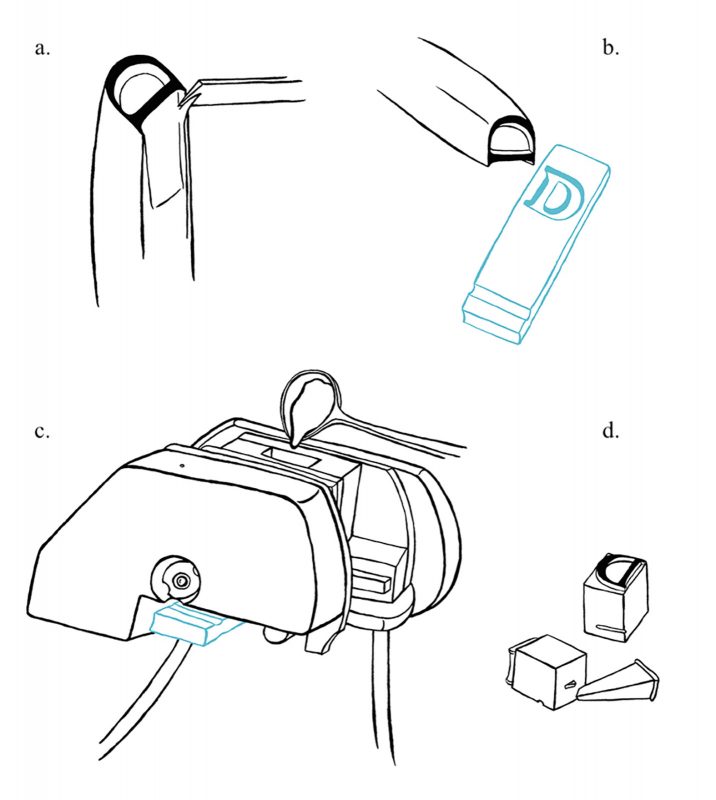

Apart from woodcuts for illustrations, compositors worked primarily with the individual pieces of lead type that constituted the textual content of a printing forme. To make the lead type, another set of craftsmen and production procedures was needed.[31] A punch cutter first carved a letter in the desired typeface on a rod of steel (Figure 9a). Similar to a woodblock, what remains after the carving stage is what will be reproduced. Afterwards, the cutter struck the punch into a small bar of copper. With a single hammer-blow, he created a matrix, a sunken impression in reverse (Figure 9b). The matrix was then placed at the base of a hand mould and secured in place by a wire spring. A typefounder then poured melted type metal — most commonly an alloy of lead, tin, and antimony– into the mould (Figure 9c). The metal solidified almost immediately in the hand mould, and the typefounder could then remove the spring and the cast type. The tail, caused by the funnel of the mould, was broken off (Figure 11d), and the type was filed to ensure every piece had the same height, as a uniform type height was essential to get an even impression onto a printed page. A piece of type was then ready to be used to print. Naturally, this seemingly simple process required a high level of skill and much practice to master. Indeed, a major part of Joseph Moxon’s Mechanick Exercises (1683–1684), one of the first comprehensive printed manuals to describe early modern printing-house practices, is dedicated to cutting and casting types.[32] With a punch, a matrix, and a mould, hundreds to thousands of identical pieces of type can be produced. Thus, the possibility of reproducing and disseminating an author’s texts by arranging and rearranging letters into words, sentences, paragraphs, and pages became infinite with the type-casting technology.

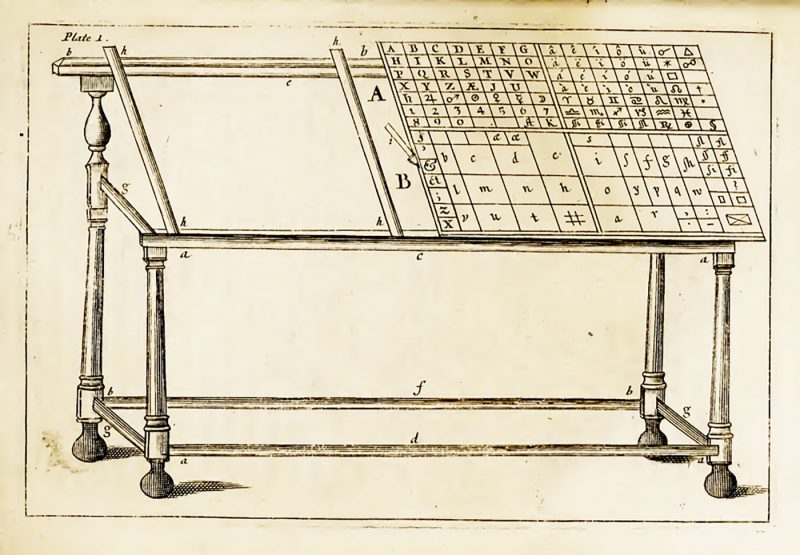

The cast pieces of type alone were insufficient for a compositor to do his job; he needed additional devices, or rather an entire typesetting station, to perform his work. The goal of the typesetting stage was to compose the typographic design of a page on a printing forme [Figure 7]. The type was arranged in type cases, divided into small compartments, with each containing a particular letter [Figure 10]. The compartments were not of equal size because some letters, such as ‘e’ and ‘a’, were used much more frequently than others, such as ‘z’. The compartments were also not arranged in alphabetical order, but with the more frequently used letters placed at the most accessible area (mainly the center) of the case.[33] Depending on the language, there would be one or a pair of type cases for a typeface. For typefaces in blackletter, usually Germanic languages, one large case would be more common because only one kind of capital would be designed. For typefaces that have alphabets with both large and small capitals, such as the Roman and the italic, two type cases would be used for better organisation.[34] Herbals usually include capitals and italics for a Roman typeface, thus, the compositor would most likely have worked with two type cases to set the type. Standing in front of the type cases, the compositor would use a composing stick to help him assemble the pieces of letters. The indented area on the stick was where the pieces of type would go. Figure 11 shows an adjustable composing stick made with metal, but the Officina Plantiniana used wooden non-adjustable ones set to the widths of a column in different formats.[35] When setting the type, there was a little notch on the side of the pieces of type to help the compositor check their orientation. Letter by letter, the compositor picked up the required pieces of type to form a sentence. Once the space on the composing stick was filled, the compositor would transfer the types onto a galley (marked A in Figure 11), which is a wooden board with three sides to keep the pieces of type from falling out. The galley was where the compositor arranged each line in the composing stick into a forme; it was also on this surface that woodblocks were incorporated into the texts and next to the type.[36] Once a page was set, the compositor slid the entire layout onto a stone table near the type cases to lock it in a chase (marked G in Figure 11), a frame that kept the type and woodblocks in place during printing. A chase was usually made of iron, but wooden ones were also used at the Plantin Press.[37] To make sure that the type and woodblock(s) were firmly secured in a chase, the compositor would hammer wooden wedges, called furniture, into the empty spaces; then a forme was set and ready to go under the press for the print run.

A skillful compositor worked with a great sense of accuracy and delicacy because his tasks mostly related to handling small pieces of type and adjusting minute differences to level the forme.[38] First, a compositor needed to be literate to read the manuscripts and very familiar with the arrangement of the compartments in the type case(s), as his knowledge largely affected the speed at which he could pick up and arrange the type. Similar to how a woodblock prints an image in reverse, a letter type is a reversal of a printed letter. Thus, type needed to be set from left to right (Figure 12). Additionally, when the type was placed in the composing stick, it appeared upside down from the compositor’s point of view. More critical, however, was a compositor’s ability to set the type without looking at the letters, other than the occasional quick check to ensure accuracy, because doing so would slow down the process. The notch on the side of a piece of type served as a quick feature to verify that the type was set in the right orientation without constantly glancing at them. Thus, the touch of the fingers replaced the sight of the eyes to perform the work at an increased speed.[39] A compositor’s skill in reading a manuscript, picking up the correct letters, and placing them in order using multiple senses ultimately affected how accurately and quickly a page could be composed. Too many spelling mistakes would greatly slow down the printing process as all the incorrect letters would need to be replaced with correct ones after proofreading.

For the madder block, however, the more pivotal aspect was how it was placed into the forme. Most of the botanical blocks in the collection of the Museum Plantin-Moretus are shorter than type height. During Plantin’s time, type height was not yet universally standardised. The surviving types for different typefaces in the MPM collection measure between 2.5cm to 2.6cm, whereas most MPM botanical woodblocks range from 2cm to 2.4cm, with the madder block at 2.2cm. Having the blocks shorter than the types ensured that they could be used with different typefaces at the Plantin Press, but also created more challenges for the compositor because the blocks needed to be leveled with the rest of the types on the forme. To do so, the compositor needed to add backings — normally sheets of paper — underneath the blocks to raise them to type height. For a skilled compositor, this would not have been a difficult job, but it added another step to the process and hence slowed down the typesetting stage. This was an especially important factor in the creation of the large herbals by the three botanists, when more than one thousand woodblocks needed to be incorporated into formes. Furthermore, a compositor needed to have the practical skill to secure a forme in a chase. This was a vital step because all the hard work to set the types and images could go to waste if the forme was disassembled when being transported to a press. Locking the forme was comparable to fitting pieces into a puzzle: a compositor would need to find the right size furniture in order to hammer the elements in place. These technical skills of a compositor place the madder block into different contexts so that the image could illustrate the plant descriptions of the botanists.

Printing Type and Images Together

The ‘tool’ of the pressmen — the hand press — was another important technological invention for book printing. The mechanisms of a press, such as a press for wine or printing textiles, were already available for other trades before the hand press took its form.[40] These presses, however, were inadequate for book printing. A wine press, for example, can only achieve vertical motion: its platen can only be moved up and down, which makes it almost impossible to ink a forme efficiently. The first hand presses resolved this problem by adding a horizontal motion. The carriage (Figure 8) moves the forme back and forth on a rail. A pressman could then turn the crank to position the carriage underneath the platen after each inking and move it back for the next inking.[41] Being able to ink a forme subsequently creates another challenge because paper is easily dirtied during the movement. To keep the paper clean, the system of frisket and tympan was installed (Figure 8). The tympan, a double frame secured to the press by hinges, keeps the paper in place during printing. The frisket has a window to allow the texts to be printed, but covers the margins to protect them from picking up unwanted ink.[42] These two modifications gave the early modern hand press its distinctive appearance and features. While individual parts would continue to be revamped to improve the printing quality, the mechanism of the hand press remained largely unchanged from the mid-sixteenth century to the eighteenth century.[43] With the hand press, a forme can yield a high number of sheets containing the same information through the same method of relief printing for a woodblock. To ink a forme, the inker took a pair of inking balls and applied a layer of printing ink onto the forme. The inking table was usually a stand with a stone top by the press. The thick and sticky ink would be spread out on the stone top. The pair of inking balls (Figure 8), sometimes called dabbers, was used exclusively until towards the end of the eighteenth century when rollers replaced them as the primary tool to ink a forme.[44] An inking ball had a round and broad surface to enable a quick and uniform application of ink, and the pressmen usually made the inking balls out of leather stuffed with wool.[45] Inking balls were not expensive tools to produce, but they required regular maintenance. The leather covering and wool filling of an inking ball needed to be renewed, as they quickly wore out in the inking process. It was this constant purchase of materials that added to the cost of the tools.[46] Thus, before starting to ink the forme, an inker would need to have the skills to make his tools.

During the printing stage, consistency and precision are the two major factors that ensure the quality of the printed pages. The aim of the inker and the printer (the pressmen) would be to reduce the differences between each printed sheet. The description of the inker’s task is simple, but there are many nuances in the process that greatly affect this work.[47] Ink needs to be applied in a thin and uniform layer, enough to give a print high contrast, but not so much as to cause the groove to be filled with ink. An uneven layer might result in a partially unprinted image or page; too little ink could yield a grey impression; and too much ink could cause the lines of an image and/or the letterforms to become too thick and undefined. For the printing matrices, in particular, the inking process not only determined the quality of the final printed image, but also how much damage would occur to the blocks. For example, upon a close look at the madder block, we can see the edges of the raised lines of the roots are slightly curved [Figure 13]. The edges of a freshly cut line would have a sharp angle. The curve is wear and tear from the inking with the inking balls rubbing the edges of the lines — and in a similar fashion from the cleaning with rags after a print run — instead of from the press, as the press would push down evenly onto the block. Although visible, this damage is considered minute, as it has not yet interfered with the printing quality of the madder block.[48] A good inker, thus, could reduce the wear to a minimum to prolong the career of the woodblocks.

To complete the printing of a forme, the printer would need a supply of paper in addition to access to a press. Paper was another force that drove early modern European book printing forward.[49] It was not cheap, and it continued to be one of the major costs in book production well into the sixteenth century. At the Officina Plantiniana, an average of sixty to sixty-five percent of the cost to produce a book was paper, with the percentage increasing to seventy-five percent for some large printings.[50] Nevertheless, it was significantly more affordable than parchment, and a large supply of it was much more feasible.[51] The papers for the quires of the three botanists’ herbals would have been either imported from France or locally made in Antwerp. During the sixteenth and seventeenth centuries, the Plantin Press consumed a large quantity of paper that was mostly delivered by manufacturers from these two regions.[52] To make it more malleable and to improve the adhesion of the ink, the paper would need to be wet before it could be impressed. A printer would thus need a basin to contain water and soak the paper for his work. Both brass and copper basins are found in the inventory of the Plantin Press. Therefore, to capably perform printing, a printer would need to have a good handle on the equipment of the press and the material of paper.

There were many details a printer needed to pay attention to in order to ensure that the printed pages were consistent in quality. In the second volume of his Mechanick Exercises, Moxon wrote extensively about how a printer should perform every step of the printing process. Many of his descriptions relate to adjusting the various parts of a press or the printer’s movements to get to the proper strength, speed, or position to obtain a good printed impression. For example, he recommended that, before starting a print job, a printer should adjust the foot step that was normally positioned underneath the carriage to best match his height. If the foot step was too far, it would hinder the printer’s strength to pull the bar effectively, and hence reduce the force needed to produce a clear impression.[53] Therefore, such knowledge in the mechanics of the press, including how to level the platen so that it would give an even press onto the forme, were significant to the successful printing of a book. Similarly, how moist a piece of paper was affected how it would receive the ink. The paper should be damp but not dripping after being run through the water in the basin. Depending on the quality of the paper (strong or weak), the printer would need to alter the amount of time the sheet was immersed in the water basin. The wet paper would be piled into a stack and wrapped in damp cloths to keep it moist until it was time to print.[54] The instances above represent a few of the many aspects a printer needed to check before the actual printing process.

When operating the press, the most important skills are precision and speed. It has been estimated that the pressmen could produce 250 impressions on one side of the paper in one hour.[55] This means that in about fifteen seconds the inker would need to ink the forme, and the printer would need to place the paper onto the tympan, close the frisket, roll the carriage under the platen, and pull the bar to press, roll the carriage back, open the frisket, remove the printed sheet, and place it on a drying rack. Therefore, the pressmen needed to work in tune and be extremely precise with their work to complete the last stage of a block’s printing job. In short, the accuracy and delicacy in the work of the compositor and the consistency and precision of the pressmen, working at a rapid pace, was what supported the high number and quality of print jobs at the Officina Plantiniana that created the many impressions of the madder image in the early modern period.

Conclusion

As previously stated, the madder block illustrated the plant in twelve botanical treatises throughout the sixteenth and seventeenth centuries [Table 1]. Most of these treatises were printed in Antwerp within the premises of the Officina Plantiniana, while the physical books and the printed illustrations were disseminated throughout Europe. However, the madder block did travel, together with the majority of the botanical blocks in the stock. Between 1583 and 1585, Plantin relocated to Leiden due to political disturbances in Antwerp, and he established a new branch of the Officina Plantiniana, which continued to thrive under the care of the Raphelengius family.[56] The Cruydt-Boeck, a Dutch translation of Dodoens’s Stirpium, came off the Leiden press in 1608 and again in 1618, for which the Antwerp office sent more than 1,300 blocks for the first edition and close to 1,500 for the second, including the madder block.[57] The woodblocks’ third trip abroad was even more significant. The Herball by John Gerard, for instance, is regarded as a highly important early modern English herbal, despite allegations of plagiarism. Gerard’s herbal is primarily a translation of Dodoens’s Stirpium, first published in 1597 and illustrated by approximately 1,800 woodblocks loaned from the Frankfurt printer Nicolaus Bassaeus.[58] Gerard did not credit Dodoens in the treatise, which led to questions about the plagiaristic nature of his work.[59] Two decades after the death of Gerard, Adam Islip, Joice Norton, and Richard Whitakers printed a new edition in London with revised text by apothecary Thomas Johnson, this time illustrated by the stock of the Plantin Press. In 1632, the madder block, as well as another more than 1,300 botanical blocks, were packed in twenty-one boxes and shipped across the sea to London.[60] The new edition of Gerard’s The Herball was published in 1633, but the blocks remained in England for a much longer period than agreed upon and anticipated, for the London printers would not release them until 1636, after another reprint of Gerard’s herbal was out on the market.[61]

From Antwerp to Leiden and London, the print staff of the several presses handled the madder block to transform the printing matrix into a printed madder illustration. The precise print run for each book is uncertain, but it has been estimated that 800 copies would be a standard number for a big herbal of Dodoens, Clusius, and Lobelius at the Plantin Press.[62] Presuming this would have been similar for Gerard’s herbal, the madder block would have been inked and sent under the press for a minimum of 9,600 times. Little by little and with each printing, the madder block and the other botanical blocks ready-to-hand gradually became darker and darker as the printing ink seeped through the surface and into the grain of the blocks. In the fullness of time, the printing matrices became the black woodblocks. As this chapter has shown, the process of the blocks becoming black is supported by many individuals. The skills and the embodied knowledge of the draftsman, the cutter(s), and the printing staff transformed the woodblock again and again. Even though the tasks of the printing staff — the compositor, the printer, and the inker — appear to be technical and insignificant at first, they are essential parts in printing books and black and white illustrations in relief printing.[63] The largely circulated printed pages using the madder block transmitted the depiction and description of this medicinal and dyeing plant throughout Europe. The deep and rich black complexion of the madder block testifies to the fastidious efforts of the craftsmen and print staff who produced these copiously illustrated early modern herbals at the Officina Plantiniana and contemporaneous printers and publishers.

Bibliography

Adam, Renaud. “Living and Printing in Antwerp in the Late Fifteenth and Early Sixteenth Centuries. A Social Enquiry,” in Netherlandish Culture of the Sixteenth Century: Urban Perspectives, ed. Ethan Matt Kavaler and Anne-Laure van Bruaene (Turnhout: Brepols Publishers, 2017).

Arber, Agnes. Herbals: Their Origin and Evolution, 3rd ed. (Cambridge: Cambridge University Press, 1986).

Blunt, Wilfrid, and Sandra Raphael. The Illustrated Herbal (London: Frances Lincoln Publishers, 1994).

Bowen, Karen L., and Dirk Imhof. “Reputation and Wage: The Case of Engravers Who Worked for the Plantin-Moretus Press,” Simiolus: Netherlands Quarterly for the History of Art, 30 (2003), 161–195.

Carter, Harry. A View of Early Typography (Oxford: Clarendon Press, 1969).

Clement, Richard W. “A Survey of Antique, Medieval, and Renaissance Book Production,” in Art into Life: Collected Papers from the Kresge Art Museum Medieval Symposia, ed. Carol Garrett Fisher and Kathleen L. Scott (East Lansing, MI: Michigan State University Press, 1995), 9–47.

De Nave, Francine, and Dirk Imhof, eds. Botany in the Low Countries (End of the 15th Century–Ca. 1650). Antwerp: The Museum Plantin-Moretus/The Stedelijk Prentenkabinet, 1993.

Dodoens, Rembert. Stirpium historiae pemptades sex (Antwerp: Christophe Plantin, 1583).

Egmond, Florike. “The Garden of Nature: Visualizing Botanical Research in Northern and Southern Europe in the 16th Century,” in From Art to Science: Experiencing Nature in the European Garden, 1500–1700, ed. Juliette Ferdinand (Treviso: ZeL Edizioni, 2016), 18–33.

Eisendrath, Erna Rice. “Portraits of Plants. A Limited Study of the ‘Icones,” Annals of the Missouri Botanical Garden, 48 (1961), 291–327.

Engel, H. “Over enkele origineelle teekeningen, naar welke houtblokken voor Dodonaeus’ Cruydtboeck gesneden zijn,” Nederlandsch Kruidkundig Archief, 53 (1943), 46–55.

Febvre, Lucien, and Henri-Jean Martin. The Coming of the Book: The Impact of Printing, 1450–1800 (London: NLB, 1976).

Gerard, John. The herball, or, Generall historie of plantes, facsimile ed. (New York: Dover Publications, 1975).

Givens, Jean A., Karen M. Reeds, and Alain Touwaide, eds. Visualizing Medieval Medicine and Natural History, 1200–1550 (Alderschot and Burlington: Ashgate, 2006).

Griffiths, Antony. The Print Before Photography: An Introduction to European Printmaking, 1550–1820 (London: The British Museum, 2016).

Hind, Arthur M. An Introduction to A History of Woodcut, Dover ed. (New York: Dover Publications, 1963).

Imhof, Dirk. “Return My Woodblocks at Once: Dealings Between the Antwerp Publisher Balthasar Moretus and the London Bookseller Richard Whitaker in the Seventeenth Century,” in The Bookshop of the World: The Role of the Low Countries in the Book-Trade, 1473–1941, ed. Lotte Hellinga, Alastair Duke, Jacob Harskamp, and Theo Hermans (‘t Goy-Houten: Hes & De Graaf, 2001), 179–190.

Johns, Adrian. “Ink,” in Materials and Expertise in Early Modern Europe. Between Market and Laboratory, eds. Ursula Klein and Emma C. Spary (Chicago and London: University of Chicago Press, 2010), 101–124.

Kockelbergh, Iris. “The Rich Collection of Woodblocks of the Museum Plantin-Moretus and Its use in the Officina Plantiniana,” in Ulisse Aldrovandi: Libri e immagini di Storia naturale nella prima Età moderna, ed. Giuseppe Olmi and Fulvio Simoni (Bologna: Bononia University Press, 2018), 109–118.

Landau, David, and Peter Parshall. The Renaissance Print, 1470–1550 (New Haven and London: Yale University Press, 1994).

Louis, A. Geschiedenis van de plantkunde. Eerste periode. De plantkennis in dienst van farmacie en landbouw. Van Oudheid tot Renaissance. (Ghent: Scientia, 1977).

Mattioli, Pietro Andrea. Commentarii in sex libros Pedacii Dioscoridis Anazarbei de medica materia (Venice: Officina Valgrisiana, 1565).

Mielke, Hans, Ursula Mielke, and Ger Luijten, eds. Peeter van der Borcht, The New Hollstein Dutch and Flemish Etchings, Engravings and Woodcuts 1450–1700, 6 vols. (Ouderkerk aan den IJssel: Sound & Vision Publishers, 2005–2007.).

Moran, Bruce T. “Preserving the Cutting Edge: Traveling Woodblocks, Material Networks, and Visualizing Plants in Early Modern Europe,” in The Structures of Practical Knowledge, ed. Matteo Valleriani (Cham: Springer, 2017), 393–419.

Moxon, Joseph. Mechanick Exercises: Or, The Doctrine of Handyworks Applied to the Art of Printing (London: S.N., 1683).

Pettegree, Andrew. The Book in the Renaissance (New Haven and London: Yale University Press, 2010).

Rabb, Theodore. A Sixteenth-Century Book of Trades: Das Ständebuch (Palo Alto, CA: The Society for the Promotion of Science and Scholarship, 2009).

Sabbe, M. “Een en ander over Dodoens’ Cruydboeck-uitgaven van 1608 en 1618 en de Van Ravelingen’s,” De Gulden Passer, 15 (1937), 89–106.

Smith, Helen. Grossly Material Things: Women and Book Production in Early Modern England (Oxford: Oxford University Press, 2012).

Stijnman, Ad. Om bucke te prenten op papir: het boekdrukprocédé in Europa tussen 1550 en 1880 (Amsterdam: Centraal Laboratorium voor Onderzoek van Voorwerpen van Kunst en Wetenschap te Amsterdam, 1992).

Swan, Claudia. “Illustrated Natural History,” in Prints and the Pursuit of Knowledge in Early Modern Europe, ed. Susan Dackerman (Cambridge, MA, and New Haven and London: Harvard Art Museums / Yale University Press, 2011), 186–191.

Voet, Leon. The Golden Compasses: A History and Evaluation of the Printing and Publishing Activities of the Officina Plantiniana at Antwerp, 2 vols. (Amsterdam: Vangendt & Co., 1969–1972).

Voet, Leon. The Plantin Press, 1555–1589: A Bibliography of the Works Printed and Published by Christopher Plantin at Antwerp and Leiden, 6 vols. (Amsterdam: Van Hoeve, 1980–1983).

Woodward, Marcus. Gerard’s Herbal: The Essence Thereof Distilled by Marcus Woodward (London: Minerva, 1974).

[1] Dodoens, Stirpium, 349.

[2] De Nave and Imhof, Botany in the Low Countries, 40–41; Swan, “Illustrated Natural History,” 186.

[3] Egmond, “The Garden of Nature,” 26–30.

[4] De Nave and Imhof, Botany in the Low Countries, 19–21.

[5] Louis, Geschiedenis van de Plantkunde, 421and 437.

[6] De Nave and Imhof, Botany in the Low Countries, 106; Voet, The Plantin Press, vol. 2, 833–834.

[7] On an introduction to the European tradition, see Blunt and Raphael, The Illustrated Herbal; on more in-depth discussions on this issue, see Givens, Reeds, and Touwaide, Visualizing Medieval Medicine and Natural History.

[8] On the woodblock collection of the Museum Plantin-Moretus, see Kockelbergh, “The Rich Collection of Woodblocks,” 109–118.

[9] On historical printing ink, see Johns, “Ink,” 110; Stijnman, “Om bucke te prenten op papier,” 39–57.

[10] Adam, “Living and Printing in Antwerp,” 83.

[11] On an important recent study on the reusing and recycling of woodblocks in the early modern period, see Moran, “Preserving the Cutting Edge,” 393–419.

[12] Voet, The Plantin Press, vol. 3, 1410–1411.

[13] On a brief introduction of printing matrices in printmaking, see Landau and Parshall, The Renaissance Print, 21–28. In the history of printing and typography, however, a printing matrix usually means the (copper) matrix for casting metal types, which will be discussed in the next section of this chapter.

[14] Griffiths, The Print Before Photography, 44.

[15] Voet, The Golden Compasses, vol. 2, 221–222.

[16] Voet, The Golden Compasses, vol. 2, 226.

[17] De Nave and Imhof, Botany in the Low Countries, 47. On the biography and works of Peeter vander Brocht, see Mielke, Mielke, and Luijten, Peeter van der Borcht, vol. 1, xvii–xxvii.

[18] Voet, The Golden Compasses, vol. 2, 199 and 211.

[19] De Nave and Imhof, Botany in the Low Countries, 49–50.

[20] On the culture of copying plant portraits, see Eisendrath, “Portraits of Plants,” 291–327.

[21] Mattioli, Commentarii, 920.

[22] De Nave and Imhof, Botany in the Low Countries, 51.

[23] Landau and Parshall, The Renaissance Print, 22; Voet, The Golden Compasses, vol. 2, 228.

[24] Engel, “Over enkele origineelle teekeningen,” 46–55. In tracking down the drawings, it was discovered that the Amsterdam Zoological Museum no longer exists and the collection was transferred to several places, including the special collections at University of Amsterdam Library, Artis Library, and the Naturalis Biodiversity Center, among possibly others. None of the abovementioned institutions have identified the sketches as part of their collections. However, it is possible that they are in the restricted parts of the institutions’ archives that are not available at the moment.

[25] The interpretation of the illustrations is aided by the translations provided by Rabb, A Sixteenth-Century Book of Trades, 33 and 35.

[26] Hind, An Introduction to A History of Woodcut, 7; Landau and Parshall, The Renaissance Print, 7 and 23.

[27] Griffiths, The Print Before Photography, 47.

[28] Bowen and Imhof, “The Case of Engravers,” 166.

[29] This chapter adapts American spelling for terminology, with the exception of forme. The English spelling is selected to specifically refer to the object of a printing forme.

[30] Pettegree, The Book in the Renaissance, 23.

[31] On more extensive discussions of the punch-cutting and type-casting processes, see Carter, A View of Early Typography, 5–22; Febvre and Martin, The Coming of the Book, 56–60; Pettegree, The Book in the Renaissance, 23–25.

[32] Moxon, Mechanick Exercises, 129–196.

[33] Voet, The Golden Compasses, vol. 2, 143.

[34] Voet, The Golden Compasses, vol. 2, 143.

[35] Most of the composing sticks in the museum inventory are the wooden non-adjustable ones.

[36] There might be different practices to insert the woodblocks during a different step, but this was the most efficient way to do so according to the expert during a workshop on typesetting.

[37] There are many wooden chases in the museum inventory, but it is not yet clear why there are chases made with different materials because only iron chases are mentioned in Voet, The Golden Compasses, vol. 2, 147.

[38] Febvre and Martin, The Coming of the Book, 62.

[39] Febvre and Martin, The Coming of the Book, 62.

[40] Pettegree, The Book in the Renaissance, 25.

[41] Febvre and Martin, The Coming of the Book, 64; Voet, The Golden Compasses, vol. 2, 133.

[42] Febvre and Martin, The Coming of the Book, 64.

[43] Febvre and Martin, The Coming of the Book, 65; Voet, The Golden Compasses, vol. 2, 134–135.

[44] Johns, “Ink,” 119.

[45] Johns, “Ink,” 117; Moxon, Mechanick Exercises, 306–312; Voet, The Golden Compasses, vol. 2, 141.

[46] Voet, The Golden Compasses, vol. 2, 150.

[47] Johns, “Ink,” 117.

[48] The majority of the MPM blocks could still reproduce clearly printed images for woodblock catalogues after almost 400 years and hundreds to thousands of impressions, suggesting that the early modern inkers were quite skillful to keep the matrices in good conditions.

[49] Febvre and Martin, The Coming of the Book, 30.

[50] Voet, The Golden Compasses, vol. 2, 19.

[51] Febvre and Martin, The Coming of the Book, 40; Voet, The Golden Compasses, vol. 2, 19.

[52] Voet, The Golden Compasses, vol. 2, 25–28.

[53] Moxon, Mechanick Exercises, 297.

[54] Moxon, Mechanick Exercises, 303–306.

[55] Clement, “A Survey,” 35.

[56] Voet, The Golden Compasses, vol. 1, 105 and151.

[57] De Nave and Imhof, Botany in the Low Countries, 108. On the publication of the Dutch editions, see Sabbe, “Een en ander over Dodoens' Cruydboeck-uitgaven,” 89–106.

[58] Gerard, The Herball, vi; De Nave and Imhof, Botany in the Low Countries, 124.

[59] Arber, Herbals, 129–130; Woodward, Gerard’s Herbal, xv.

[60] Imhof, “Return My Woodblocks at Once,” 179 and 184.

[61] Imhof, “Return My Woodblocks at Once,” 179 and 184.

[62] De Nave and Imhof, Botany in the Low Countries, 44.

[63] It should be noted that while this chapter discusses labor through male contributors, as the tasks examined were mostly performed by men, women also played some roles in the printing industry. For a case study on women’s contributions in early modern printing, see Smith, Grossly Material Things.